Technical Guide: GSI Audiometer Calibration Standards

Calibration is the foundation of accurate audiometric testing, ensuring that GSI audiometers provide precise, reliable measurements that comply with international standards. This comprehensive technical guide covers calibration requirements, procedures, and standards compliance for GSI audiometry equipment used in clinical, research, and screening applications.

#

Understanding Audiometer Calibration

##

Definition and Importance

Audiometer calibration is the process of verifying and adjusting equipment performance to ensure accurate sound pressure levels, frequency outputs, and timing characteristics meet established standards. Proper calibration ensures:

- Diagnostic Accuracy: Reliable threshold measurements for clinical decision-making

##

Types of Calibration

Biological (User) Calibration

Exhaustive (Professional) Calibration

#

International Calibration Standards

##

ANSI S3.6-2018: Specification for Audiometers

Scope and Application:

ANSI S3.6 is the primary U.S. standard governing audiometer performance requirements, calibration procedures, and verification methods.

Key Requirements:

| Parameter | Tolerance | Measurement Method | Verification Frequency |

|-----------|-----------|-------------------|------------------------|

| Output Sound Pressure Level | ±3 dB (125-4000 Hz), ±5 dB (6000-8000 Hz) | Coupler measurement with calibrated microphone | Annual |

| Frequency Accuracy | ±1% (125-4000 Hz), ±3% (6000-8000 Hz) | Electronic frequency counter | Annual |

| Harmonic Distortion | <2.5% (125-4000 Hz), <5% (6000-8000 Hz) | Spectrum analyzer measurement | Annual |

| Rise/Fall Time | 20-200 ms for tone onset/offset | Oscilloscope measurement | Annual |

| Linearity | ±1 dB over 5 dB range | Sound level meter verification | Annual |

Reference Equivalent Threshold Sound Pressure Levels (RETSPL):

ANSI S3.6 defines the reference levels that establish 0 dB HL at each frequency.

| Frequency (Hz) | TDH-39/49 Headphones | Insert Earphones (ER-3A) | Bone Oscillator (B-71) |

|----------------|----------------------|--------------------------|------------------------|

| 125 | 45.0 dB SPL | 28.0 dB SPL | 45.0 dB SPL |

| 250 | 27.0 dB SPL | 14.0 dB SPL | 35.0 dB SPL |

| 500 | 13.5 dB SPL | 5.5 dB SPL | 26.5 dB SPL |

| 1000 | 7.5 dB SPL | 0.0 dB SPL | 20.0 dB SPL |

| 2000 | 11.0 dB SPL | 3.0 dB SPL | 23.5 dB SPL |

| 4000 | 9.5 dB SPL | 5.5 dB SPL | 35.0 dB SPL |

| 8000 | 13.0 dB SPL | 15.5 dB SPL | 40.0 dB SPL |

##

IEC 60645 Series: Electroacoustics - Audiometric Equipment

IEC 60645-1: General Requirements

International standard covering basic audiometer specifications and performance requirements.

IEC 60645-2: Equipment for Speech Audiometry

Specifications for speech audiometry equipment including calibration of speech materials and presentation systems.

IEC 60645-4: Equipment for Extended High-Frequency Audiometry

Requirements for audiometers capable of testing frequencies above 8000 Hz (up to 20000 Hz).

IEC 60645-5: Instruments for the Measurement of Aural Acoustic Impedance/Admittance

Specifications for tympanometers and acoustic reflex testing equipment.

##

Additional Relevant Standards

ANSI S3.1-2018: Maximum Permissible Ambient Noise Levels

Defines acceptable background noise levels for audiometric testing environments.

ANSI S3.39-2018: Specification for Instruments to Measure Aural Acoustic Impedance

Calibration requirements for tympanometry equipment.

ISO 389 Series: Reference Zero for the Calibration of Audiometric Equipment

International reference standards for audiometric zero levels.

#

GSI-Specific Calibration Procedures

##

GSI AudioStar Pro Calibration

Biological Calibration Check:

1. System Preparation

- Power on AudioStar Pro and allow 15-minute warm-up period

- Verify environmental conditions meet ANSI S3.1 requirements

- Select "Calibration" from main system menu

- Choose "Biological Check" option

2. Threshold Verification

- Test operator hearing at 1000 Hz and 4000 Hz bilaterally

- Use established baseline thresholds from operator's audiometric record

- Accept results within ±5 dB of established baselines

- Document results in system calibration log

3. System Response Check

- Verify patient response system functionality

- Test both manual and automatic response modes

- Confirm proper channel identification (right/left)

- Check tone interruption and timing functions

Professional Calibration Setup:

Required Equipment:

Calibration Sequence:

1. Environmental Verification

- Measure ambient noise levels per ANSI S3.1

- Document temperature and humidity conditions

- Verify electromagnetic compatibility (EMC) environment

- Check AC power quality and grounding

2. Electronic Performance Tests

- Verify internal timing and logic functions

- Check digital-to-analog conversion accuracy

- Test patient response system operation

- Confirm data storage and retrieval functions

3. Acoustic Output Measurements

- Measure output levels at all test frequencies

- Verify linearity across intensity range

- Check harmonic distortion levels

- Measure rise/fall time characteristics

- Test crosstalk between channels

##

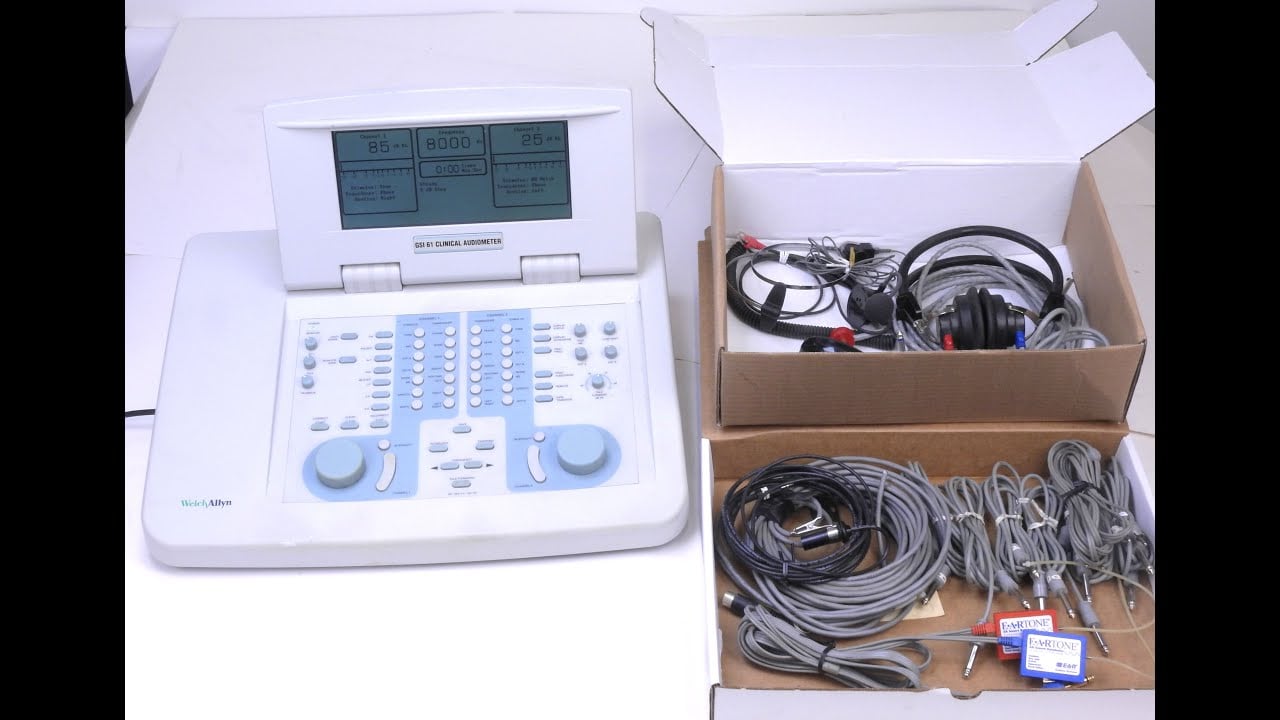

GSI 61 Clinical Audiometer Calibration

Daily Biological Check:

1. Set frequency selector to 1000 Hz

2. Position TDH-39 headphones properly

3. Begin threshold search at known baseline level

4. Use modified Hughson-Westlake procedure

5. Record threshold and compare to established baseline

6. Repeat at 4000 Hz for comprehensive check

7. Document results and accept/reject status

Professional Calibration Procedure:

Preparation Phase:

Measurement Protocol:

| Test Parameter | Measurement Points | Acceptance Criteria | Adjustment Procedure |

|----------------|-------------------|---------------------|---------------------|

| Frequency Accuracy | All test frequencies | ±1% (125-4000 Hz) | Internal oscillator adjustment |

| Output Level | All frequency/intensity combinations | ±3 dB (per ANSI S3.6) | Attenuator calibration |

| Linearity | 5 dB steps over 40 dB range | ±1 dB maximum deviation | Electronic gain adjustment |

| Distortion | Maximum output levels | <2.5% THD | Signal path optimization |

| Crosstalk | Both channels at maximum output | >40 dB isolation | Channel separation verification |

##

GSI 18 Screening Audiometer Calibration

Field Calibration Checks:

1. Battery Verification

- Check battery voltage under load conditions

- Verify voltage stability during maximum output

- Document battery replacement dates and performance

2. Simplified Biological Check

- Test operator thresholds at screening frequencies only

- Use pass/fail criteria appropriate for screening applications

- Document results on portable calibration log

3. Environmental Assessment

- Measure ambient noise at testing locations

- Verify compliance with screening audiometry noise limits

- Document environmental conditions for each testing site

#

Calibration Equipment and Standards

##

Primary Standards Traceability

National Institute of Standards and Technology (NIST)

U.S. primary standards for acoustic measurements provide traceability chain for audiometer calibration.

Calibration Chain:

1. Primary Standard: NIST-maintained acoustic standards

2. Secondary Standard: Accredited calibration laboratory standards

3. Working Standard: Service provider measurement equipment

4. Field Standard: Daily calibration check procedures

##

Required Measurement Equipment Specifications

Sound Level Meter Requirements:

Coupler Specifications:

#

Regulatory Compliance Requirements

##

FDA Medical Device Regulations

Device Classification:

GSI audiometers are classified as Class II medical devices under FDA regulations, requiring:

- 510(k) premarket notification for substantial equivalence

Calibration Documentation:

##

OSHA Noise Exposure Requirements

29 CFR 1910.95 - Occupational Noise Exposure:

##

State and Local Regulations

Many jurisdictions have additional requirements for:

#

Safety Precautions

⚠️ CRITICAL CALIBRATION SAFETY PROTOCOLS

- Never exceed maximum safe output levels during calibration procedures (typically 130 dB SPL)

#

Quality Assurance Integration

##

Calibration Record Management

Required Documentation:

Record Retention Requirements:

##

Performance Trending

Statistical Analysis:

Predictive Maintenance:

#

Troubleshooting Calibration Issues

##

Common Calibration Problems

Frequency Drift:

Output Level Instability:

Excessive Harmonic Distortion:

##

Advanced Diagnostic Techniques

Signal Analysis:

Environmental Impact Assessment:

#

Professional Service Integration

##

Service Provider Qualifications

Required Certifications:

Service Documentation:

##

Calibration Intervals

Standard Intervals:

Interval Optimization:

#

Conclusion

Proper calibration of GSI audiometry equipment is essential for accurate diagnosis, patient safety, and regulatory compliance. Understanding and implementing comprehensive calibration standards ensures reliable equipment performance and supports quality hearing healthcare delivery.

Regular calibration, proper documentation, and professional service integration create a robust quality assurance framework that protects patients, providers, and institutions. Staying current with evolving standards and best practices is crucial for maintaining calibration program effectiveness.

Investment in proper calibration procedures and equipment ultimately enhances diagnostic accuracy, reduces liability risks, and demonstrates commitment to professional excellence in hearing healthcare.

---

Legal Disclaimer: This calibration guide is for informational purposes only. Always follow official calibration standards, manufacturer procedures, and regulatory requirements. Professional calibration services should be performed only by qualified, certified technicians using traceable standards.